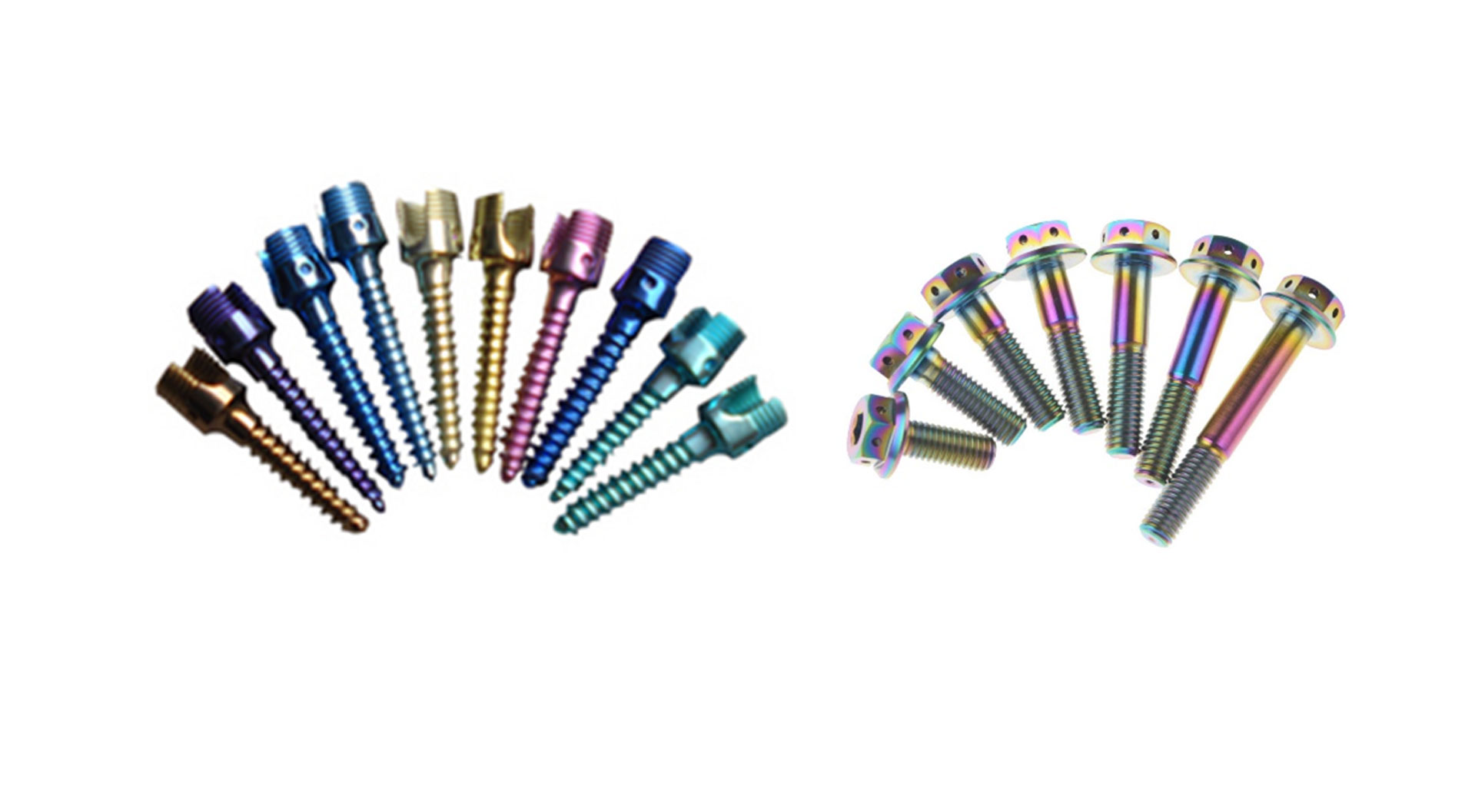

Sulfuric Acid Anodizing(Clear and Color)

The most common and cost-effective anodizing process. Provides excellent abrasion and corrosion resistance. Sulfuric acid Coatings of moderate thickness 1.8 μm to 25 μm are known as Type II. It is also named as MIL-A-8625.Anodizing treatments that provide protection to the surface of the products while allowing the natural beauty to shine through.